Magnetic Straight Welding Swing Model Oscillation Auto Weld carriage

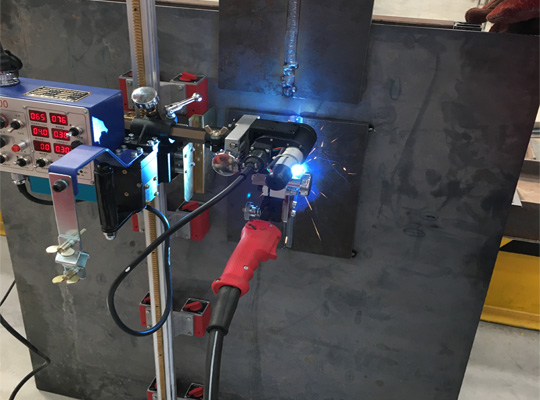

HK-100 Magnetic Straight Welding Swing Model Oscillation Auto Weld carriage

HK-100 swing welding trolley is automatic. It can gain more wide welded seam at a time.You can adjust swing speed, swing angle, offset position of centre and length of stay. It suits for vary specs beads. In non-welding state, the biggest trolley speed is 1300mm/min.The magnetron hand grip can decrease a few magnetism, so it is convenient to clear iron waste and moving trolley.

The from HK-100 small car essence, the control box, the X-Y slippery piece, the gun tongs, the direction round, leads a track straightly etc. the parts constitute.

1) Little car owner's body: BE also a small car to drive device, include electrical engineering, the planet decelerates a box, driving wheel gear and leading to an etc..

2) Control a box. Can regulate all actions of the small car, the detailed contents makes reference to follow-up "the control panel elucidation"

3) The Horizontal move device: the Be welding to keep to sew(the if gather to pack)

to make use of this device to adjust the torch position, avoid multifariously

ambulation leading a track.

4) The torch is tiny to adjust a slippery piece. BE the device that regulates the gun

position, weld in the middle can carry on a top and bottom or so tiny adjust.

5) Swing a machine: Weld process in various weld mode to need him to carry out.

6) The gun clips to hold a machine. BE the device of the fixed gun, maintain and the

adjustment is a convenient gun to dismantle to unload. The torch must clip

tightly, notice and clip Be conducting electricity part, then will cause short-circuit

or electric shock.

7) AC outlet: In order to circumscribe the electric cable electric outlet, this the

machine connects a ground of line to also connect with each other with this

electric outlet. This electric cable electric outlet is responsible for a small car and

sends the conjunction and the electricity supply of the silk machine.(Electric cable

of another on carrying two branches, a connects to send the silk machine, the

another connects power supply.)

8) Hand handle: The ambulation equips originally, please fist this hand handle.

9 ) Leaving to match the hand handle, pulling to move this hand handle can let very

conveniently the small car move freely on the orbit.

10) Lead a track straightly. The convenient and small car runs about route. The gearing has strong dint always the magnetic iron, letting to lead a track to adsorb the work piece firmly on, the orientation is various to weld a need.

11) The Magnetic iron: The strong dint leaves the match type magnetic iron, the please control all the switch to go to "OFF" while moving to lead a track.

12) Lead to a round: Along the female material noodles roll over, guide accurate weld

the device of the part.

13) The Gun: the Keep the gun or curved gun, the customer make choice of

purchase.

Main technical parameter

1.Weight | 8.4Kg (Included swing device) | |

2.Outline dimension | 430 mm x 280 mm x 290 mm | |

3.Driving mode | Four rims driving (Rubber rim) | |

4.power | DC 24V | |

5.Swing motor | DC24V | |

6.Speed | 30~~800 (mm/min)( Display by nixie tube) | |

7.Tracking mode | Rail | |

8.Range of adjusting welding torch | Up and down:40mm Front and rear:60mm. Range of working angle:±45° Range of adjusting angle: 10° | |

9.Operation function | Choose walk direction | Left and right |

Swing speed | 0~100 | |

Swing angle | ±15° | |

Adjust walk speed | 0~130cm/min | |

Length of stay on left or right | 0~2.5 s | |

Set position of deviation | 0~±8° | |

10.Choose swing model |

| |

Welding technical parameters

welding wire diameter welding parameter | Φ1.2mm | Φ1.4mm | Φ1.6mm | |

current(A) | Down hand welding | 120-300 | 150-380 | 180-430 |

flush fillet welding | 120-280 | 150-320 | 180-380 | |

horizontal welding | 120-280 | 150-300 | 180-330 | |

voltage(U) |

| |||

distance between nozzle and workpiece(H) |

| |||

welding extension length(L) | The length is about 10 times welding wire diameter. It is L=10d | |||

Contents of package

1. | complete machine | 1set |

2. | The straight rail(1.8 m) | 1set |

3. | Standard power wire (16M) | 1set |

4. | Fuse(2A) | 2set |

5. | hex wrench | 1pc |

6. | Operating manual , Certificate of qualification | 1pc each |

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-