Multi-direction all position gas cutter for curved plate

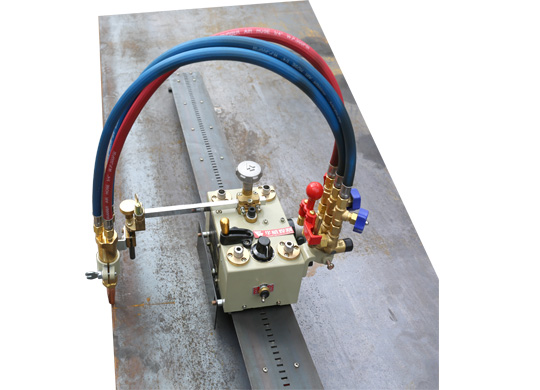

CG1-13 Multi-direction all position gas cutter for curved plate

“CG1-13” multi-direction gas cutter is designed well. It is beautiful and portable. The system uses silicon control to adjust speed. It is easy to operate. The machine moves on the rail, which is distributed with nickel cobalt permanent magnet steel. There are strong adsorption and convenient loading and uploading. The rail can adhere to vertical, cross direction, inverted and curve face to cut. The structure is compacted, the operation is easy and it has a wide range of use. So, it is suitable for shipyard, boiler, bridge, metallic departments to do gas cutting, such as batching and skew surface cutting.

Specifications

1. Weight (body) | :15 kg |

2. Machine dimension | :230×200×230mm |

3. Speed control | :Silicon control |

4. Power source | :AC 220V, 50Hz |

5. Cutting speed | :50~750mm/min |

6. Cutting thickness | :6-30mm |

7.Curvature of cutting rough straight steel plate | :R≥700MM(in following picture) |

9. Tip(30°) | :GO2—1#、2#、3# |

10.Motor | :DC 110V 0.5A 30W ;10000r/min |

Contents of package

1. Body | 1 set |

2. Tip | 3 pcs each (acetylene) |

3. Gas-in connector (oxygen, acetylene | 1 set |

4. Electrical case unit assemblage | 1 set |

5.Electrical connecting line | 1 pc |

6.Rail | 1.6m/pc x2 |

7. Specification sheets and certificate of qualification | 1 pc each |

8.Torch unit assemblage | 1 set |

9.Torch holder | 1 set |

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-