Double side auto welding carriage

HK-5T-II Double side auto welding carriage

HK-5T-II which is suitable for continuous horizontal fillet welding structure is double side welding device.Volume is small; weight is light; moving and installing are convenient.Carriage can weld while walking forward and backward.Carriage’s movements have high stability because of synchronous four-wheel drive.Permanent magnets are installed in the lateral magnetic roller, and the guide wheels are at the top of roller, to avoid the car away from the welding line.

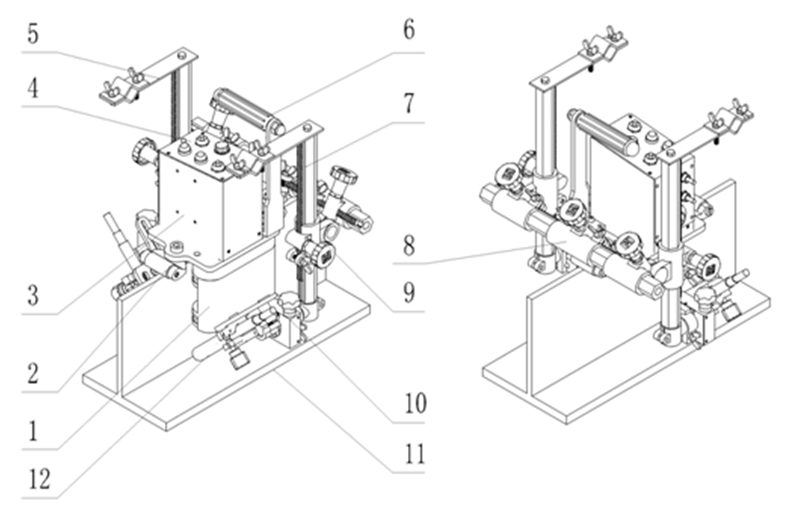

1.Drive part: It is a device to drive the carriage, constituted by two sets of magnetic wheels, transmission gears, and the drive motor. Due to large magnetic wheel suction, they can firmly adsorb on steel plate, to ensure that the carriage will not change its walking path.

2. Guide wheel: the carriage starts, because the carriage's own weight focus on the two guide wheels, guide wheels guide the carriage to run along the steel plate end face.

3. Electrical box: the machine's electrical components are installed in it, at the same time to ensure that the electrical components are not affected by dust.

4. Control panel: It can adjust all actions of carriage. Please refer to “explanation of control panel”.

5. Welding gun cable clamp: a device to fix the welding gun cable, for the convenience of welding gun, the screw type cable clip is adopted.

6. Portable handle: it is convenient for the machine to be transited and carried.

7.Lifting lever: it is connected with the welding gun holder, through its lifting movement, can adjust the height of welding gun, to ensure that the gun and seam are in the best position.

8. Transverse bracket seat: can adjust two welding guns left side and right side distance.

9. Mobile lifting seat: adjust the welding guns up and down distance.

10. Angle adjustment device: can fine-tune the angle of welding gun and seam.

11. Work piece

12. The Gun: the Keep the gun or curved gun, the customer make choice of purchase.

Main technology parameter

TYPE | HK-5T-II | |

size | 330mm×280mm×160mm | |

Power | DC24V | |

Weight | 10KG | |

Range of welding torch adjusting | up-down:200mm | range of working angle:360° |

left-right:120mm | range of adjusting angle:10° | |

walking speed | 50~1900mm/min(nixie display indicator) | |

Moving | our-wheel drive(rubber wheel) | |

Operating function | No.1welding/not welding | No.2 welding/not welding |

start walking | stop walking | |

choose walking direction(left-right) | walking speed (0~850mm/min) | |

Welding parameter

welding wire diameter welding parameter | Φ1.2mm | Φ1.4mm | Φ1.6mm | |

current(A) | downhand welding | 120-300 | 150-380 | 180-430 |

flush fillet welding | 120-280 | 150-320 | 180-380 | |

horizontal welding | 120-280 | 150-300 | 180-330 | |

voltage(U) |

| |||

distance between nozzle and workpiece(H) |

| |||

welding extension length(L) | The length is about 10 times welding wire diameter. It is L=10d | |||

Contents of package

NAME:Standard angle welding Auto carriage

MODEL NUMBER:HK-5T-II

Accessories:

1. Regulated power supply DC24V one set

2. Standard power cord 220V/20M one set

3. 2P torch control line 500mm one set

4. Fuse 220V/2A two sets

5. Inner hexagon spanner one set

6. Instruction book one set

7. Conformity certificate one set

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-